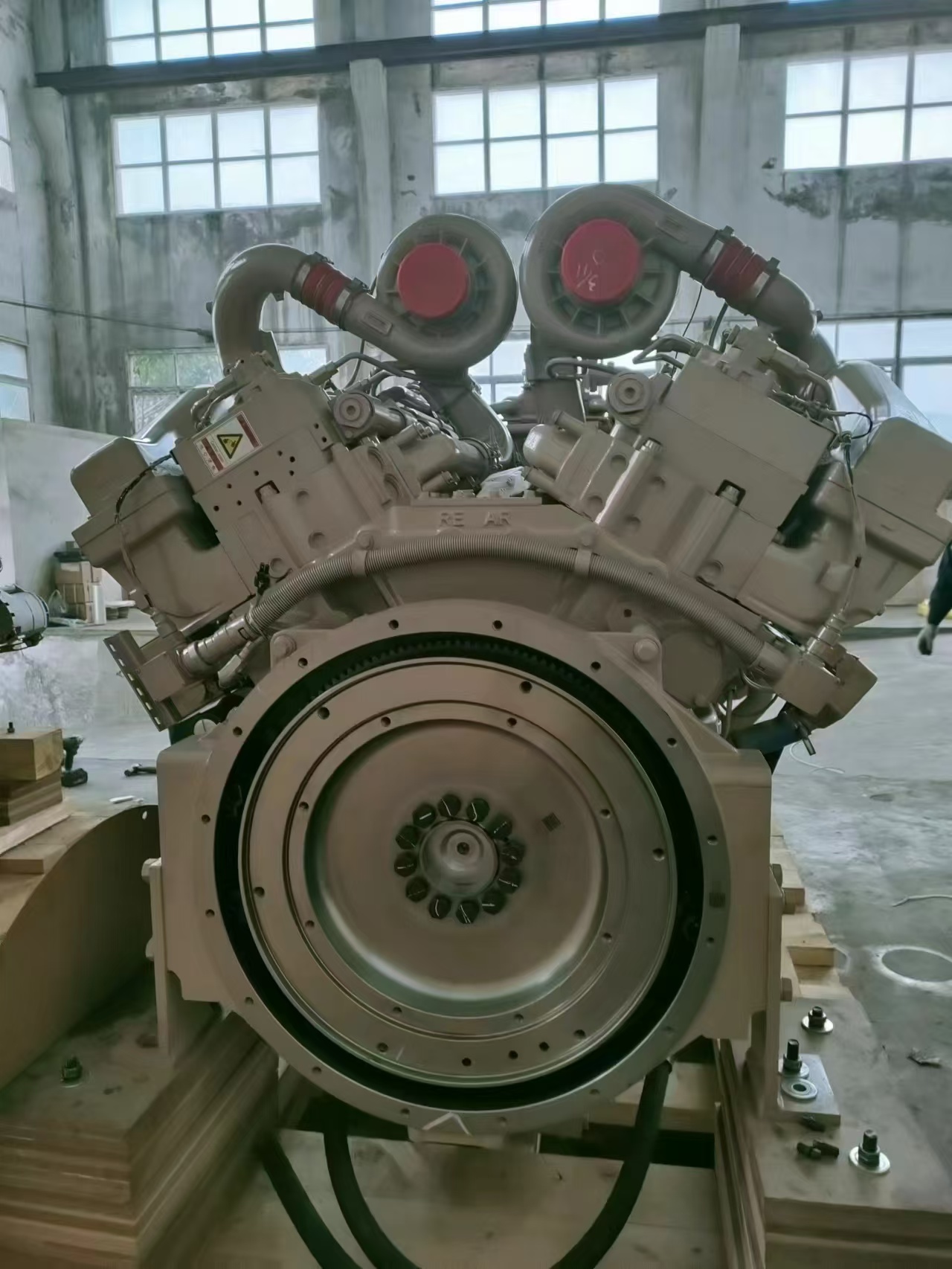

QSK38-C1600 Industrial Application Engine

| Engine Model | QSK38-C1600 |

| Maxi. Rating | 1600 HP @1800 RPM |

| Compression Ratio | 13.9 : 1 |

| Type | 4 Cycle, 60° Vee; 12 Cylinder |

| Fuel System | PT |

| Aspiration | Turbocharged & Aftercooled |

| Emission Standard | Euro II |

| Displacement | 37.7 L |

| Bore * Stroke | 159 mm × 159 mm |

| Packing Size (L * W * H) | 2300 mm * 1700 mm * 2000 mm |

General Infomation of CCEC QSK38-C1600 Industrial Engine

| General Infomation of CCEC QSK38-C1600 Industrial Engine | |||

| Engine Model | QSK38-C1600 | Emission Standard | U.S. EPA Tier 2 |

| Advertised Power | 1,600 HP (1,193 kW) @ 1,900 RPM | Peak Torque | 4,604 lb-ft (6,242 N-m) @ 1,500 RPM |

| Curve & DatAsheet | FR-6869 | Governed Power | 1,600 HP (1,193 kW) @ 1,900 RPM |

| Compression Ratio | 15.0 : 1 | Packing Size (L * W * H) | 2260 mm * 1339 mm * 2332 mm |

| Type | V-12 Cylinder 4-Stroke 4-Valve | Displacement | 2300 in³ ( 37.7 L ) |

| Fuel System | Cummins MCRS | Bore * Stroke | 6.26 in * 6.26 in / 159 mm * 159 mm |

| Aspiration | Turbocharged & Water-Air Intercooler | Minimum Low Idle Speed | 600 RPM |

| Configuration | D233040CX03 | Maximum Low Idle Speed | 1200 RPM |

| CPL Code | 3380 | Minimum speed for full load sustained operation | 1700 RPM |

| Engine Sound Pressure Levels3 (Noise) Data of CCEC QSK38-C1600 Industrial Engine | |||

| Top Side | 105.1 dBa | Right Side | 101.6 dBa |

| Left Side | 101.8 dBa | Front Side | 102.4 dBa |

| Exhaust | 94.3 dBa | ||

| General Engine Data of CCEC QSK38-C1600 Industrial Engine | |||

| Maximum overspeed capability | 2150 RPM | Maximum installed engine power angle | 6 ° |

| Mass moment of inertia of rotating components (excluding flywheel) | 35.40 in-lbf-sec2 / 4.00 kg-m2 | Maximum installed engine tilt angle | 6 ° |

| Engine weight (mining market)⁴-Approximate Dry Weight | 9943 lb / 4510 kg | Engine weight (mining market)⁴-Approximate Wet Weight | 10675 lb / 4842 kg |

| Engine weight (locomotive market)⁴-Approximate Dry Weight | N / A | Engine weight (locomotive market)⁴-Approximate Wet Weight | N / A |

| Engine weight (oil and gas market)⁴– Approximate Dry Weight | N / A | Engine weight (oil and gas market)⁴– Approximate Wet Weight | N / A |

| Engine Mounting Data of CCEC QSK38-C1600 Pump Engine | |||

| Moment of Inertia — X-Axis (Roll) | 3434 in-lbf-sec² / 388 kg-m2 | Moment of Inertia — Y-Axis (Pitch) | 12533 in-lbf-sec² / 1416 kg-m2 |

| Moment of Inertia — Z-Axis (Yaw) | 12621 in-lbf-sec² / 1426 kg-m2 | Center of Gravity — From Rear Face of Block | 31.54 in / 801 mm |

| Maximum Crankshaft Thrust Bearing Load Limit — Intermittent Load | N / A | Maximum Crankshaft Thrust Bearing Load Limit — Continuous Load | N / A |

| Maximum Static Bending Moment at Rear Face of Block | 4499 lb-ft / 6100 N.m | Maximum Bending Moment Available From Front of Crankshaft — 90 Degrees | 1610 lb-ft / 2183 N.m |

| Center of Gravity — From Engine Centerline to Left Side of Engine (as Viewed From Rear of Engine) | N / A | Maximum Bending Moment Available From Front of Crankshaft — 180 Degrees | 5660 lb-ft / 7674 N.m |

| Maximum Bending Moment Available From Front of Crankshaft — 0 Degrees | 2486 lb-ft / 3370 N.m | Maximum Bending Moment Available From Front of Crankshaft — 270 Degrees | 4382 lb-ft / 5941 N.m |

| Center of Gravity — Above Crankshaft Centerline | 6.81 in / 173 mm | ||

Performance Data of CCEC QSK38-C1600 Industrial Engine

| Performance Data of CCEC QSK38-C1600 Industrial Engine | |||||||||

| Advertised Power | Peak Torque | Advertised Power | Peak Torque | ||||||

| Engine Speed | 1,800 RPM | 1,500 RPM | Inlet Air Flow | 3,835 ft3/min | 1810 L/s | 2,771 ft3/min | 1308 L/s | ||

| Power Output | 1600 HP | 1193 kW | 1315 HP | 981 kW | Heat Rejection to LTC Coolant | 18328 BTU/min | 332 kW | 11572 BTU/min | 203 kW |

| Torque Output | 4,423 lb-ft | 5,997 N.m | 4,604 lb-ft | 6,242 N.m | Exhaust Gas Flow | 8,981 ft3/min | 4,239 L/s | 7,709 ft3/min | 3,638 L/s |

| Friction Horsepower | 188 HP | 140 kW | 119 HP | 89 kW | Exhaust Gas Temperature | 843 °F | 451 ℃ | 1,027 °F | 553 ℃ |

| Intake Manifold Pressure | 78 in-Hg | 263 kPa | 66 in-Hg | 223 kPa | Heat Rejection to Ambien Air | 5,183 BTU/min | 91 kW | 4,440 BTU/min | 78 kW |

| Turbo Comp. Outlet Pressure | 79 in-Hg | 267 kPa | 67 in-Hg | 226 kPa | Heat Rejection to Exhaust Gas | 58,206 BTU/min | 1023 kW | 52,230 BTU/min | 918 kW |

| Turbo Comp. Outlet Temperature | 403 °F | 206 ℃ | 363 °F | 184 ℃ | Heat Rejection to HTC Coolant | 23,132 BTU/min | 407 kW | 23,947 BTU/min | 421 kW |

Advantages of CCEC QSK38-C1600 Industrial Engine

Superior Environmental Adaptability

Optimized design enhances adaptability to high altitudes, extreme temperatures, and complex loads, ensuring stable output under diverse conditions.

- Exceptional Performance

Advanced Fuel Technology

Incorporates a globally leading high-pressure common rail fuel system and fully electronic control module, achieving ultra-high fuel injection pressure. Combined with a swirl harmonic intake port design and Cummins-proprietary high-pressure ratio turbocharger, it delivers peak power output and transient response.

High Efficiency and Energy Savings

Balances high torque and rapid response with excellent fuel economy, significantly reducing long-term operational costs.

- Ultra-Long Durability

Reinforced Structural Design

High-strength integrated cylinder block and head minimize mechanical stress, reduce failure rates, and ensure extended service life.

Intelligent Lubrication and Filtration System

Equipped with pre-lubrication, Centriguard centrifugal filters, CENTINEL continuous oil renewal system, and two-stage Fleetguard filters, extending maintenance intervals by 50% and reducing downtime.

- High Reliability

Compact Modular Architecture

Modular integration lowers component complexity, reduces failure rates, and delivers excellent vibration and noise control.

Stable Full-Condition Output

Maintains optimal performance under altitude variations and load fluctuations, ideal for harsh environments like mining and high-altitude operations.

- Eco-Friendly Emissions Compliance

Clean Combustion Technology

Optimized combustion chamber design complies with China Non-Road Stage III emission standards without additional aftertreatment, lowering compliance costs.

Certified Environmental Compliance

Authoritative emission certifications ensure readiness for evolving environmental regulations.

- Hassle-Free Maintenance

Smart Diagnostic Tools

INSITE software (Windows-based) enables intuitive fault diagnosis, real-time monitoring, and faster troubleshooting.

Modular and Universal Design

Highly standardized components support rapid assembly/disassembly and cross-platform compatibility, reducing spare parts inventory and maintenance costs.

Comprehensive Value

Through technological innovation and design optimization, this engine achieves a balance of power, reliability, eco-compliance, and cost-effectiveness. Ideal for non-road applications such as engineering machinery and agricultural equipment, it delivers an efficient, durable, and user-friendly power solution.