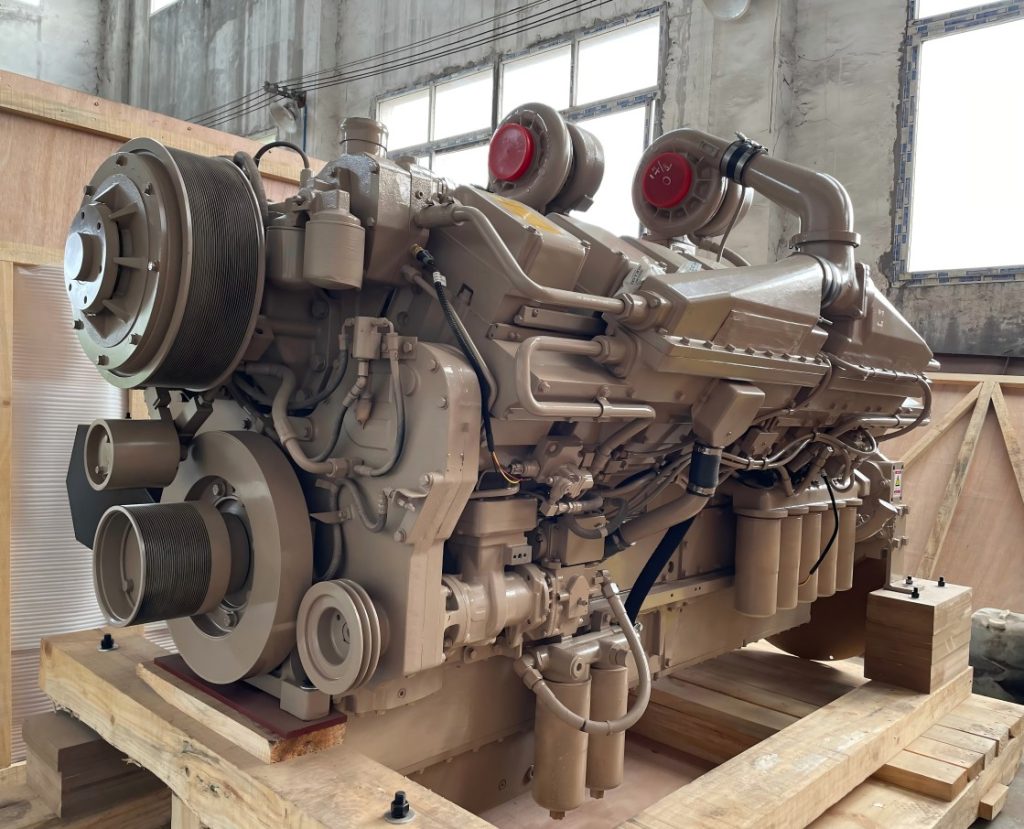

KTTA50-C2000 Industrial Application Engine

| Engine Model | KTTA50-C2000 |

| Maxi. Rating | 1600 HP @ 2100 RPM |

| Compression Ratio | 13.9 : 1 |

| Type | 4 Cycle, 60° Vee; 16 Cylinder |

| Fuel System | PT |

| Aspiration | Turbocharged & Aftercooled |

| Emission Standard | Euro II |

| Displacement | 50.3 L |

| Bore * Stroke | 159 mm × 159 mm |

| Packing Size (L * W * H) | 2690 mm * 1560 mm * 2260 mm |

| CCEC KTTA50-C2000 Industrial Engine General Infomation | ||||

| Engine Model | KTTA50-C2000 | CPL Code | 2913 | |

| Curve & Datasheet | FR 6356 | Rated Power | 1491 kW (2000 HP) @ 1900 RPM | |

| Compression Ratio | 13.8 : 1 | Torque Peak | N/A | |

| Type | 4 Cycle , 60° Vee , 16 Cylinder | Revision | 13-Jan-03 | |

| Bore * Stroke | 159 mm × 159 mm | Displacement | 50.3 L (3067 in3) | |

| Net Weight | 4946 kg | Fuel System | PT | |

| Aspiration | Turbocharger & Aftercooler | Emission Certification | U.S. EPA Tier 1 | |

| Engine Configuration | D283026CX02 | Packing Size (L * W * H): | 3000 mm * 1800 mm * 2500 mm | |

| Torque Output | Power Output | Fuel Consumption | ||||||

| RPM | lb-ft | N-m | RPM | HP | kW | RPM | lb/hp-hr | g/kW-hr |

| 1,300 RPM | 5,800 lb-ft | 7,864 N-m | 1,300 RPM | 1,436 HP | 1,071 kW | 1,300 RPM | 0.335 lb/hp-hr | 204 g/kW-hr |

| 1,500 RPM | 5,800 lb-ft | 7,864 N-m | 1,500 RPM | 1,657 HP | 1,236 kW | 1,500 RPM | 0.325 lb/hp-hr | 198 g/kW-hr |

| 1,700 RPM | 5,665 lb-ft | 7,681 N-m | 1,700 RPM | 1,834 HP | 1,368 kW | 1,700 RPM | 0.323 lb/hp-hr | 196 g/kW-hr |

| 1,900 RPM | 5,530 lb-ft | 7,498 N-m | 1,900 RPM | 2,001 HP | 1,492 kW | 1,900 RPM | 0.327 lb/hp-hr | 199 g/kW-hr |

| Scopes of Supply of CCEC KTTA50-C2000 Industrial Engine | ||||

| Fuel System | 1. Fuel Transfer Pump | Exhaust System | 1. Exhuast Manifold | |

| 2. High-Pressure Fuel Pump | 2. Turbocharger | |||

| 3. Fuel Filter | 3. Exhuast Elbow | |||

| Air Intake System | 1. Air Intake Manifold | Starting System | 1. Starter Motor | |

| 2. N/A | 2. Starter Relay | |||

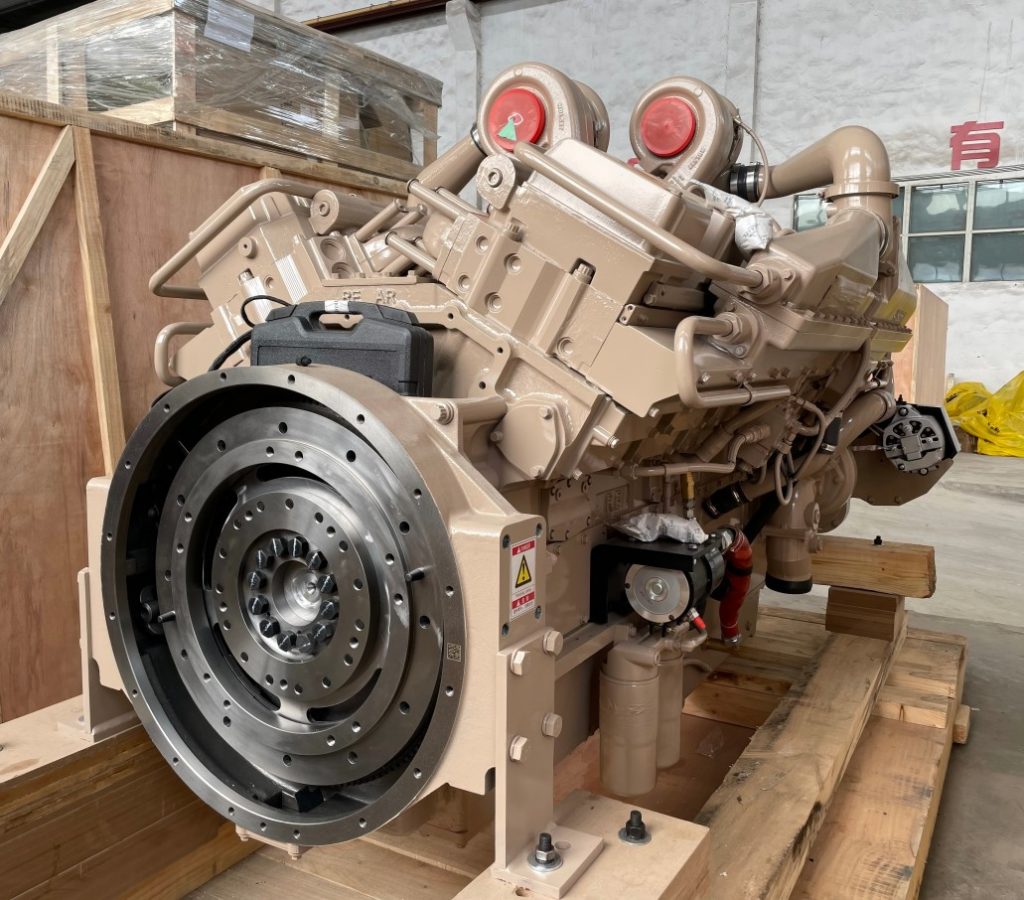

| Cooling System | 1. Water Pump | Power Output System | 1. Flywheel | |

| 2. Engine Fan | 2. Standard Flywheel Housing | |||

| 3. Standard Radiator | 3. N/A | |||

| Lubricating System | 1. Oil Pump | Charging System | 1. Charging Alternator | |

| 2. Oil Filter | 2. N/A | |||

| Engine Shut-Down System | 1. Engine Fuel Shut-Off Solenoid | Engine Mounting System | 1. Engine Mounting Bracket | |

| Engine Auiliary Accessories | 1. Air Compressor | |||

Cummins KTTA50-C200 Engine is a high-power, highly reliable diesel engine designed for heavy-duty mining machinery. Below are its common application scenarios and compatible equipment types:

1. Mining Dump Trucks (rigid/articulated)

- Ultra-large mining trucks: Suitable for dump trucks with a payload capacity exceeding 150 tons, such as:

- Terex Unit Rig MT6300 (configuration verification required)

- BelAZ 7530/7531 series (compatible with certain models)

- Komatsu 930E (typically uses Cummins QSK series, but custom versions may integrate KTA50)

2. Large Hydraulic Excavators

- Ultra-large excavators: For models with bucket capacity exceeding 20 cubic meters, such as:

- Liebherr R 9800 (custom power configuration required)

- Caterpillar 6090 FS (usually equipped with Cat engines, but modified versions may adapt KTA50)

3. Mining Drills

- Open-pit drilling equipment: Suitable for high-torque rotary blast hole drills, e.g.:

- Atlas Copco Rotary Blast Hole Drills (e.g., PV-271 series)

- Sandvik DR Series Drills

4. Large Loaders

- Wheeled/tracked loaders: For ore-handling equipment, such as:

- Komatsu WA1200 (wheeled loader; power configuration verification required)

- Caterpillar 994K (typically uses Cat engines, but special retrofits may adapt KTA50)

5. Bulldozers and Graders

- Large tracked bulldozers: E.g., Komatsu D475A (custom configuration required; typically equipped with Komatsu engines).

Key Considerations

- Compatibility verification: Specific compatibility depends on OEM designs. The Cummins engine may be offered as an optional or customized solution.

- Environmental requirements: The KTTA50-C1600 operates well in high-temperature, dusty mining environments but requires regular air and fuel filter maintenance.

- Power matching: With 1,600 HP (~1,193 kW), it is ideal for ultra-heavy machinery, but transmission systems must align with engine performance.

Note: Equipment compatibility and configurations may vary based on manufacturer specifications and custom engineering solutions.