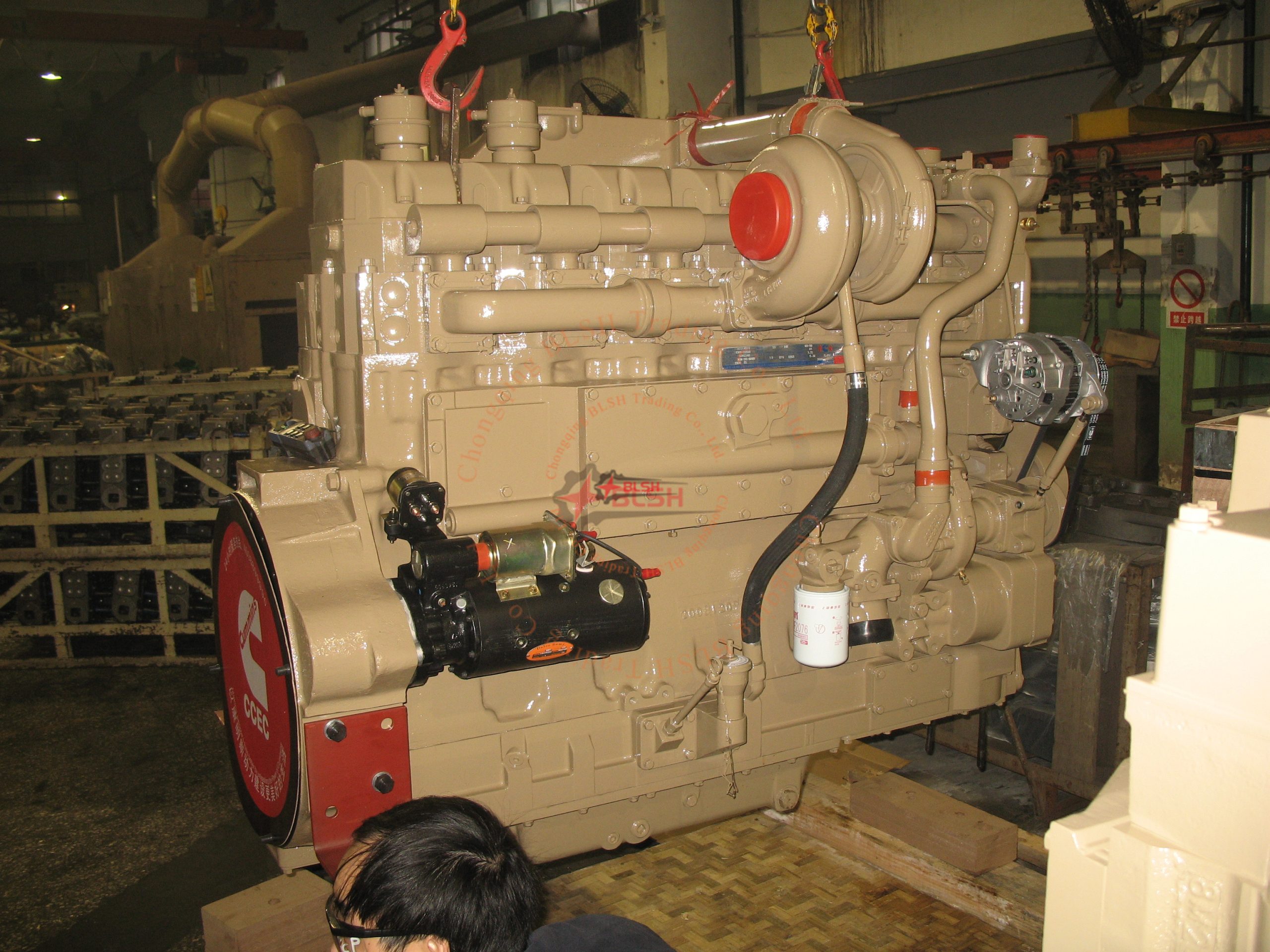

KTA19-C700 Industrial Application Engine

| Engine Model | KTA19-C700 |

| Maxi. Rating | 700 HP @ 2100 RPM |

| Compression Ratio | 13.9 : 1 |

| Type | 4 Cycle, 60° Vee; 12 Cylinder |

| Fuel System | PT |

| Aspiration | Turbocharged & Aftercooled |

| Emission Standard | Euro II |

| Displacement | 19 L |

| Bore * Stroke | 159 mm × 159 mm |

| Packing Size (L * W * H) | 2151 mm * 966 mm * 1704 mm |

| General Infomation of CCEC KTTA19-C700 Industrial Engine | |||

| Engine Model | KTTA19-C700 | Standby Power | N/A |

| Maxi. Rating | 700 HP @ 2100 RPM | Emission Standard | N/A |

| Curve & Datasheet | P-4524-B | Peak Torque | N/A |

| Compression Ratio | N/A | Displacement | 18.9 L |

| Type | 4 Cycle; In-line 6-Cylinder Diesel | Bore * Stroke | 159 mm × 159 mm |

| Fuel System | PT Fuel Pump | Dry Weight (Fan Hub to Flywheel Engine) | 1725 kg |

| Aspiration | Turbocharged & Aftercooled | Wet Weight (Fan Hub to Flywheel Engine) | 2615 kg |

| Configuration | D193077CX02 | Firing Order | 1-5-3-6-2-4 |

| CPL Code Revision | 0951 | ||

| Performance Data of CCEC KTTA19-C700 Industrial Engine | |||

| Minimum Low Idle Speed | 725 RPM | Maximum No-Load Governed Speed | 2350 RPM |

| Maximum Overspeed Capability | 2625 RPM | ||

| Breakaway Torque at Minimum Unaided Start Temperature | N/A | ||

| Cranking Torque at Minimum Unaided Start Temperature | 556 N·m | ||

| Torque Available at Clutch Engagement | 1207 N·m | ||

| Minimum Recommended Combined Converter and Hydraulic Stall Speed | 1600 RPM | ||

| Crankshaft Thrust Bearing Load Limi — Maximum Intermittent | 1500 lb | ||

| Crankshaft Thrust Bearing Load Limi — Maximum Continuous | 750 lb | ||

| Maximum Allowable Power From Front of Crankshaf | N/A | ||

| Maximum Allowable Power From Accessory Drive | 8 kW | ||

| Minimum Cranking Speed Required For Unaided Cold Start | N/A | ||

| Engine Performance Data CCEC KTTA19-C700 Industrial Engine | ||||

| MAXIMUM | CONTINUOUS | |||

| RATED | PEAK TORQUE | RATED | PEAK TORQUE | |

| Engine Speed | 2100 RPM | 1300 RPM | 1800 RPM | 1300 RPM |

| Gross Power Output | 522 kW | 401 kW | 413 kW | 340 kW |

| Torque | 2374 N.m | 2731 N.m | N/A | 2319 N.m |

| Intake Manifold Pressure | 1600 mmHg | 1219 mmHg | 1245 mmHg | 991 mmHg |

| Brake Mean Effective Pressure | 1856 kPa | 1820 kPa | 1462 kPa | 1544 kPa |

| Piston Speed | 11.1 m/s | 7.4 m/s | 9.5 m/s | 7.4 m/s |

| Friction Horsepower | 74 kW | 36 kW | 55 kW | 36 kW |

| Intake Air Flow | 792 litre/s | 467 litre/s | 590 litre/s | 420 litre/s |

| Exhaust Gas Flow — Dry Manifold | 1955 litre/s | 1166 litre/s | 1465 litre/s | 1048 litre/s |

| Exhaust Gas Temperature — Dry Manifold | 442 ℃ | 533 ℃ | 456 ℃ | 527 ℃ |

| Heat Rejection to Ambient — Dry Manifold | 25.3 kW | 38.7 kW | 18.5 kW | 29.1 kW |

| Engine Water Flow | 13.9 litre/min | 8.6 litre/min | 12 litre/min | 26.4 litre/min |

| Modifiable Components of CCEC KTA19-C700 Industrial Engine | ||||

| Air Intake System | 1. Installation Position of Air Filter | Charging System | 1. 12 V Charging Alternator for 12 v Electric System | |

| 2. Upgrade to Heavy-Duty Type Air Fitler | 2. Explosion-Proof Charging Alternator | |||

| 3. N/A | 3. Upgrading to Specified Brand and Speicifications of Charging Alternator | |||

| Exhuast System | 1. Water-Cooled Exhuast Manifold | Lubricating System | 1. Oil Pan Position | |

| 2. Water-Cooled Turbocharger | 2. Number of Dipstick | |||

| 3. Can Modify Installation Position and Direction of Turbocharger | 3. Position of Dipstick Can Choose from 6 Positions | |||

| 4. N/A | 4. Can Modify Oil Filter to be Remote Installation | |||

| Engine Shut-Down System | 1. 12 V Solenoid for 12 V Electric System | Starting System | 1. Upgrading to Specified Brand and Speicifications of Starter Motor | |

| 2. Explosion-Proof Solenoid | 2. 12 V Starter Motor for 12 V Electric System | |||

| Fuel System | 1. Upgrade to Fuel Fitler that Integrated with Fuel Transfer Pump and Fuel Pre-Hearter | Engine Auiliary Accessories | 1. All of auxiliary System can Choose Specified Brands and Specifications | |

| 2. N/A | 2. Additional Auxiliary Systems Can be Added for Special Applications | |||

| Cooling System | 1. Can Modify Engine fan Into Blower Fan or Suction Fan | Power Output System | 1. Can Modify Size of Flywheel Housing and Flywheel | |

| 2. Can Modify Central Position of Engine Cooling Fan | 2. Dual-Ear Flywheel Housing (For Twin-Starter System) | |||

| 3. Can Choose Type of Engine Fan From Mechanical Type or Electric Type | 3. Some of Models can Modify Flywheel Housing Into PTO Integrated Type | |||

| 4. N/A | 4. Engine Have Connecting Port of PTOs, That Able to Provide Power Output | |||

| Engine Mounting System | 1. Can Modify Engine Mouting Bracket | |||

The CCEC KTA19-C700 Industrial Engine offers a robust set of advantages tailored for demanding industrial applications, combining innovative engineering with proven reliability. Here’s a structured breakdown of its key benefits:

1. Durability in Harsh Conditions

- Advanced Design: Engineered to withstand extreme environments, with high-strength components and a heavy-load capacity for uninterrupted operation.

- Forged Critical Parts: Forged steel camshaft and crankshaft enhance resilience under stress, while the high-rigidity cylinder block resists deformation and pressure.

2. Integrated Design for Reduced Failures

- Monobloc Construction: Integrated cylinder block and head eliminate 40% of parts compared to conventional engines, minimizing leakage (oil/water) and lowering failure rates.

- Simplified Maintenance: Fewer components reduce wear points and maintenance complexity.

3. Superior Oil Management

- Platform Mesh Honing: Precision cylinder bore treatment optimizes oil retention, preventing leaks.

- Advanced Sealing: New piston rings and gasket crimping technology reduce oil consumption, enhancing efficiency and environmental compliance.

4. In-House Engineered Systems

- Proven Global Performance: Five core electronically controlled systems (e.g., fuel injection, cooling) are developed and validated by CCEC across diverse global applications, ensuring adaptability and reliability.

5. Fuel Efficiency and Cost Savings

- Optimized Control Strategy: Tailored algorithms align with real-world operating conditions, improving fuel economy and reducing operational costs.

6. Long Service Life

- High-Pressure Resistance: Reinforced components and rigid construction extend lifespan, even under continuous heavy use.

Summary

The KTA19-C700 excels in durability, efficiency, and reliability, making it ideal for industries like mining, construction, and power generation. Its integrated