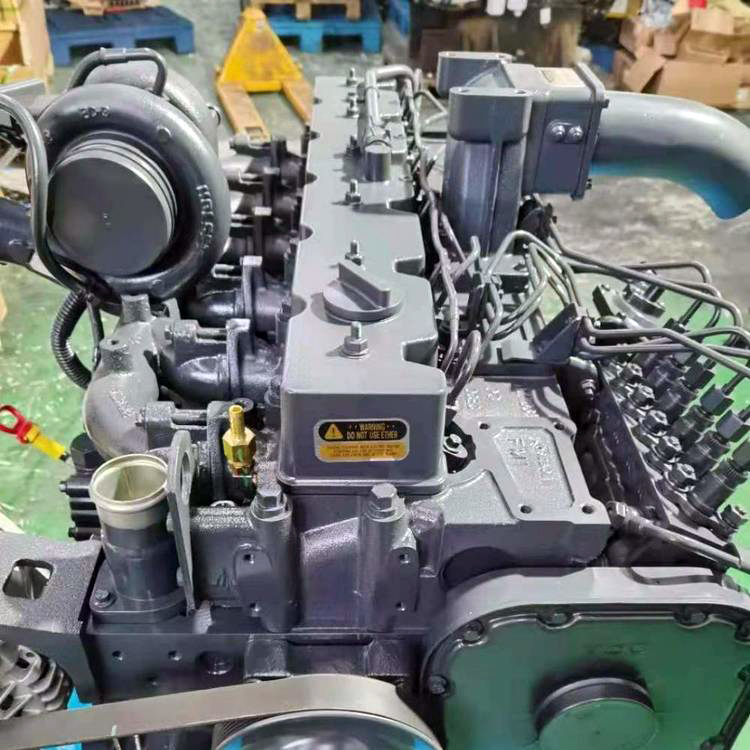

DCEC Cummins 6CTAA8.3-C145 Industrial Application Engine

| Engine Model | 6CTAA8.3-C145 |

| Rated Power / Speed: | 145 HP @ 1900 RPM |

| Peak Torque: | 542 N.m @ 1900 RPM |

| Type | 6 Cylinders, in Line |

| Fuel System | Wuxi Weifu PW2000 pump RSV speed regulator |

| Aspiration | Turbocharged & Water-Air Intercooler |

| Displacement | 8.3 L |

| Bore * Stroke | 114 mm * 135 mm |

| Packing Size (L * W * H) | 1115 mm * 716 mm * 1077 mm |

| Lead Time: | 5-15 Working Days |

General Infomation of DCEC 6CTAA8.3-C145 Industrial Engine

| General Infomation of DCEC 6CTAA8.3-C145 Industrial Engine | |

| Engine Model | 6CTAA8.3-C145 |

| CPL Code | 3672 |

| Advertised Power | 145 HP @ 1900 RPM |

| Peak Torque | 542 N.m @ 1900 RPM |

| Fuel System | Weifu PW2000 pump / RSV speed regulator |

| Engine Wet Weight | 338 kg |

| Curve No | FR93622 |

| Displacement | 8.3 L |

| Bore * Stroke | 102 mm * 120 mm |

| Aspiration | Turbocharged |

| Cylinders | 6 Cylinders, in Line |

| Rating Type | Continuous |

| Installation Data of DCEC 6CTAA8.3-C145 Industrial Engine | |

| Moment of Inertia of Rotating Components (No Flywheel) | 0.143 kg·m² |

| Center of Gravity from Front Face of Block | 262 mm |

| Center of Gravity Above Crankshaft Centerline | 160 mm |

| Maximum (Static) Bending Moment at Front Support Mounting Surface | 435 N.m |

| Maximum (Static) Bending Moment at Side Pad Mounting Surface | N/A |

| Maximum (Static) Bending Moment at Rear Face of Block | 1356 N.m |

| Moment of Inertia of Complete Engine— Roll Axis | 11.1 kg·m² |

| Moment of Inertia of Complete Engine— Pitch Axis | 19.1 kg·m² |

| Moment of Inertia of Complete Engine— Yaw Axis | 14.7 kg·m² |

Performance Data of DCEC 6CTAA8.3-C145 Industrial Engine

| Engine Performance Data Rated Power of DCEC 6CTAA8.3-C145 Industrial Engine | |||||

| Rated Power | Torque Peak | Rated Power | Torque Peak | ||

| Engine Speed | 1900 RPM | 800 RPM | Exhaust Gas Temperature | 410 °C | 600 °C |

| Gross Power Output | 108 kW | 54 kW | Heat Rejection to Ambient | 10.5 kW | 8 kW |

| Torque | 542 N.m | 640 N.m | Heat Rejection to Coolant | 45 kW | 36 kW |

| Intake Manifold Pressure | 55 kPa | 40 kPa | Heat Rejection to Fuel | 0.9 kW | 0.6 kW |

| Friction Horsepower | 11.5 kW | 7.0 kW | Engine Coolant Flow | 3.0 L/s | 2.0 L/s |

| Turbo Comp. Outlet Pressure | 56 kPa | 40 kPa | External Cooling Circuit Resistance | 15.2 kPa | 15.2 kPa |

| Intake Air Flow | 109 Ls | 60 L/s | Altitude Limitations-Intermittent | TBD | TBD |

| Exhaust Gas Flow | 239 L/s | 147 L/s | Altitude Limitations-Continuous | TBD | TBD |

| Turbo Comp. Outlet Temperature | N/A | N/A | Steady State Smoke | TBD | TBD |

Advantages of DCEC 6CTAA8.3-C145 Industrial Engine

The DCEC C series engine is engineered for high-performance, durability, and efficiency, making it ideal for heavy-duty applications under severe conditions. Here’s a breakdown of its key features and benefits:

- Bosch In-Line Fuel Pump

- Utilizes high fuel injection pressure for superior atomization, ensuring more complete combustion. This enhances fuel efficiency, reduces energy loss, and lowers emissions while delivering stronger power output. The system’s robustness also allows adaptability to varying fuel qualities.

- Holset Turbocharger with Integrated Wastegate

- Likely a turbocharger (given Holset’s expertise), it provides low-speed responsiveness, minimizing turbo lag and boosting torque at lower RPMs. The integrated wastegate optimizes boost pressure control, contributing to sustained power and efficiency across operating conditions.

- Integral Cylinder Design

- Reduces part count by 40% compared to peers, simplifying the engine architecture. This design lowers failure rates, eases maintenance, and enhances reliability—critical for high-intensity operations in sectors like construction, mining, or long-haul transport.

- Durable Cylinder Liner and Piston

- Platform mesh honing on the cylinder walls improves oil retention, reducing wear and oil consumption. Paired with corrosion-resistant high-nickel cast iron pistons, the engine withstands extreme heat and stress, extending service life and reducing downtime.

- High Power-to-Liter Ratio (27.0 kW/L)

- Outperforms many diesel engines in its class, offering exceptional power density. This makes the engine compact yet powerful, suitable for applications where space and weight are constraints but high output is essential.

Target Applications: Ideal for construction machinery, commercial trucks, agricultural equipment, and industrial uses requiring reliable, high-output performance in harsh environments.

Competitive Edge: Combines advanced technology (Bosch, Holset) with simplified, robust design to prioritize longevity, ease of maintenance, and fuel efficiency. Positioned as a cost-effective, durable alternative to international brands, particularly in markets demanding resilience under stress.

Note: While the term “supercharger” was used, Holset’s expertise in turbochargers suggests this is a turbocharged system. The engine’s focus on high power density is balanced by materials and design choices that mitigate thermal stress, ensuring durability.oad applications such as engineering machinery and agricultural equipment, it delivers an efficient, durable, and user-friendly power solution.