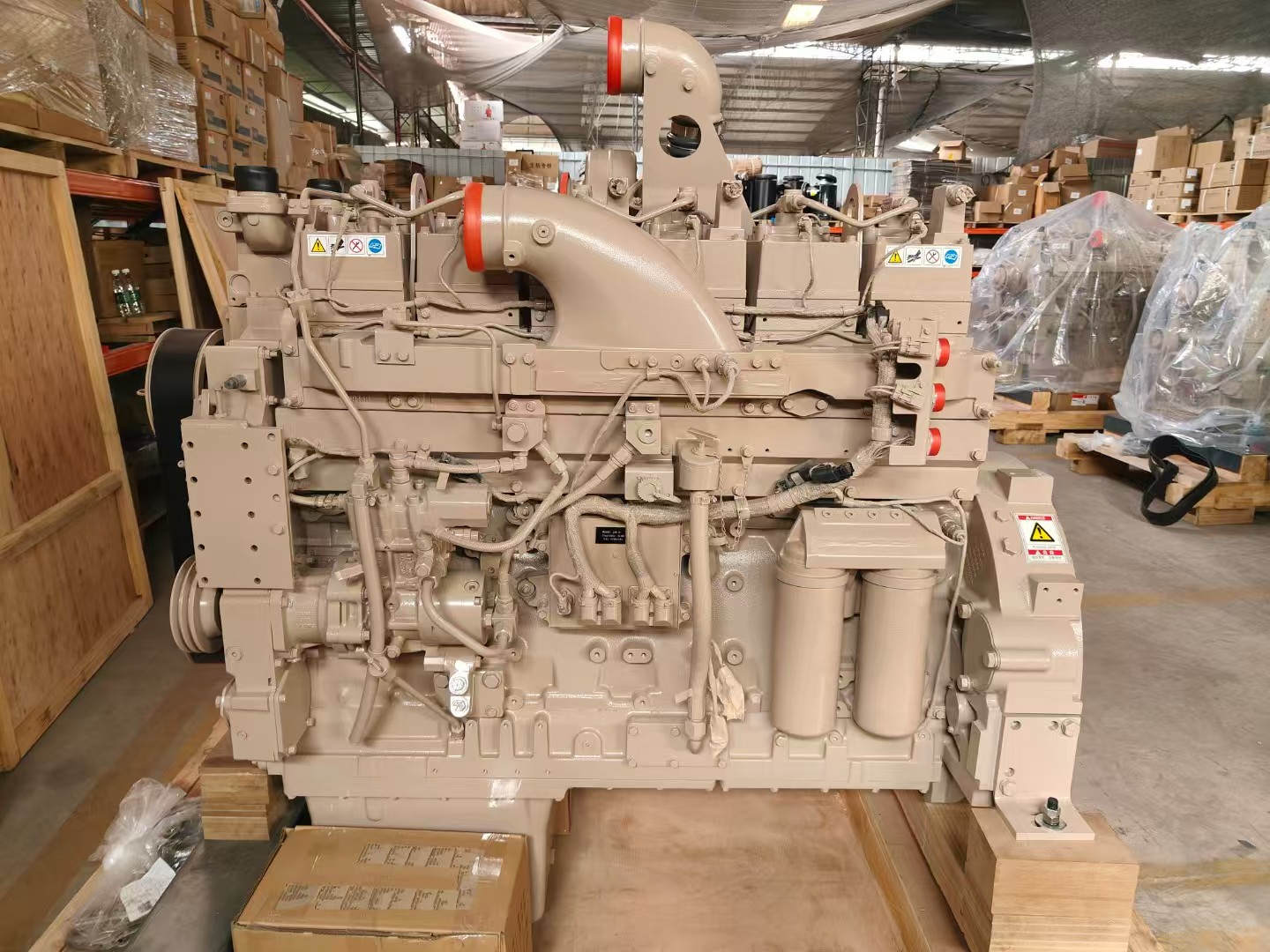

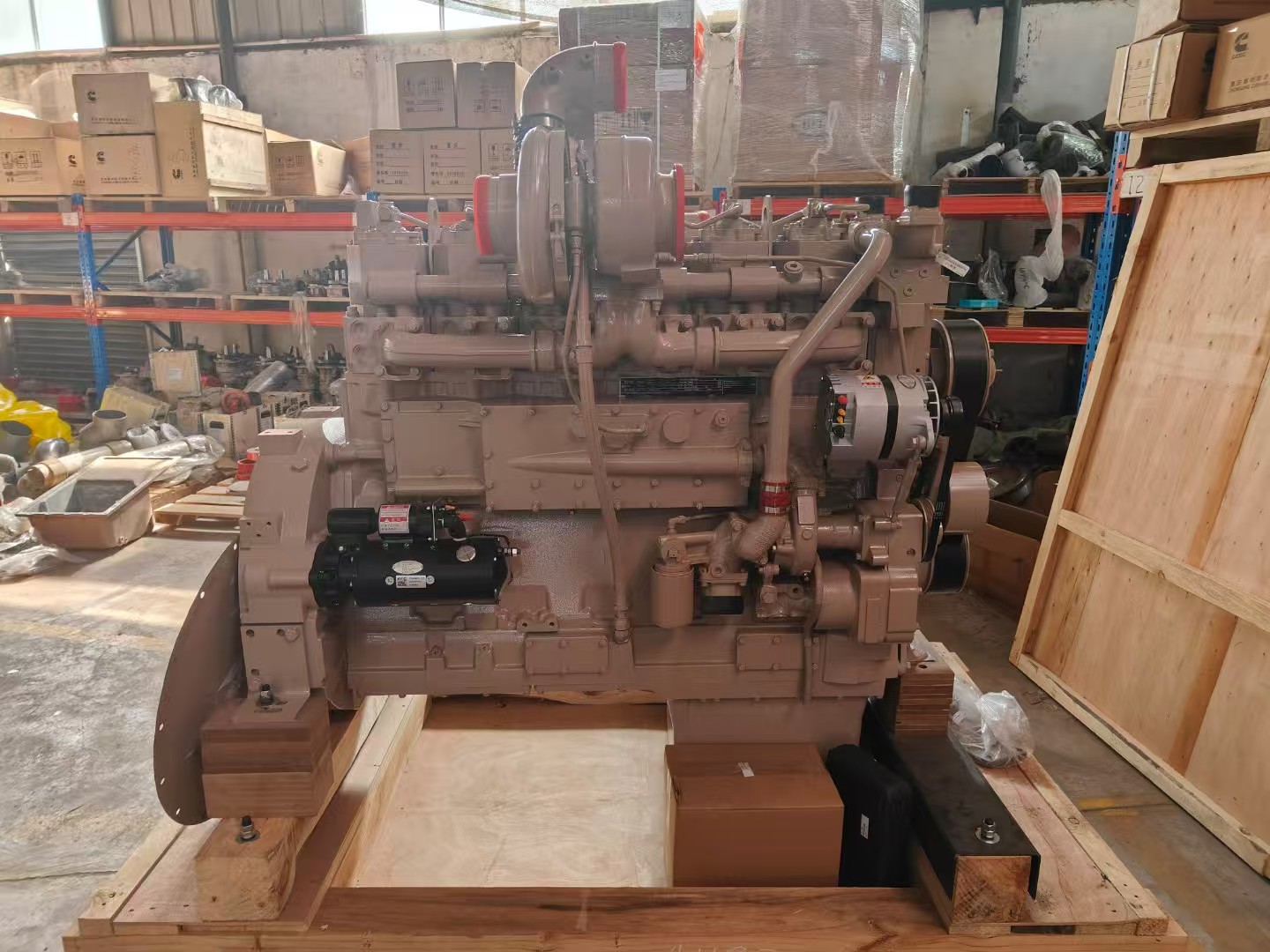

CCEC QSK19-M567 Marine Engine

| Engine Model | QSK19-M567 |

| Advertised Power | 567 kW (760 HP) @ 2100 RPM |

| Compression Ratio | 14.5 : 1 |

| Type | 4 Cycle; 6 Cylinder |

| Fuel System | MCRS |

| Aspiration | Turbocharged / LTA |

| Emission Standard | Euro II |

| Displacement | 19L |

| Bore * Stroke | 159 mm * 159 mm |

| Packing Size (L * W * H) | 2007 mm * 963 mm * 1880 mm |

General Infomation of CCEC QSK19-M567 Marine Engine

| General Infomation of CCEC QSK19-M567 Marine Main Engine | |||

| Engine Model | QSK19-M567 | Fuel pump code | ET75 |

| Curve No. | M-567 | Injector part No. | 2867147 |

| Displacement | 1150 in³ / 19 L | CPL Code | 3455 |

| Fuel System | Modular Common Rail System (MCRS) | Bore * Stroke | 159 mm * 159 mm |

| Advertised Power | 567 kW (760 HP) @ 2100 RPM | Cylinders | 6-cylinder inline |

| Turbocharger model | HX82M | Aspiration | Turbocharged / Aftercooled |

| Max. firing pressure (MPa) | 15.26 | Overload output (110 %) / Rev. (kW / RPM) | 623 / 2167 |

| Rated output / Rev. (kW / RPM) | 567 / 2100 | Advert. output / Rev. (kW / RPM) | N / A |

Scopes of Supply CCEC QSK19-M567 Marine Engine

| Scopes of Supply of CCEC QSK19 – M567 Marine Main Engine | |||

| Exhaust System | 1. Silencer | Lubricating System | 1. Oil Pump |

| 2. Bellows | 2. Oil Filter | ||

| Fuel System | 1. Fuel Pump | Starting System | 1. Starter Motor |

| 2. Oil Cut Solenoid Valve | 2. Fywheel Housing | ||

| 3. Fuel Filter | 3. Flywheel | ||

| Charging System | 1. Alternator | Control System | 1.Stadnby Control Panel |

| Cooling System | 1. Seawater Pump | ||

| 2. Heat Exchanger | |||

System Technical Data of CCEC QSK19-M567 Marine Engine

| System Technical Data of CCEC QSK19 – M567 Marine Main Engine | ||

| Fuel System | Fuel Consumption at Rated Speed | 8 GAL/hr / 31 L/hr |

| Approximate Fuel Flow to Pump | 25 GAL/hr / 93 L/hr | |

| Maximum Allowable Fuel Supply to Pump Temperature | 160 °F / 71 °C | |

| Approximate Fuel Flow Return to Tank Temperature | N / A | |

| Maximum Heat Rejection to Drain Fuel | N / A | |

| Fuel Pressure – Pump Out / Rail Mechanical Gauge | 56 PSI / 386 kPa | |

| Air System | Intake Manifold Pressure | 18 in. Hg / 61 kPa |

| Intake Air Flow | 474 CFM / 224 L/sec | |

| Heat Rejection to Ambient | 797 BTU/min / 14 kW | |

| Exhaust System | Exhaust Gas Flow | 1082 CFM / 511 L/sec |

| Exhaust Gas Temperature (Turbine Out) | 685 °F / 363 °C | |

| Heat Rejection to Exhaust (Manifold) | 955 °F / 513 °C | |

| Cooling System | Sea Water Pump Specifications | MAB 0.08.17 – 07 / 16 / 2001 |

| Pressure Cap Rating (With Heat Exchanger Option) | 7 PSI / 50 kPa | |

| Engines without Low Temperature Aftercooler (LTA) Jacket Water Aftercooled Engine (JWAC) | ||

| Coolant Flow to Engine Heat Exchanger | 55 GAL/min / 208 L/min | |

| Standard Thermostat Operating Range (Start to Open) | 180 °F / 82 °C | |

| Standard Thermostat Operating Range (Full Open) | 201 °F / 94 °C | |

| Heat Rejection to Engine Coolant3 | 5294 BTU/min / 93 kW | |

CCEC QSK19-M567 Marine Engine Product Advantages

The QSK19 series marine engine is a high-performance, efficient, and reliable engine designed for marine applications, incorporating advanced technologies to meet stringent emissions standards and operational demands. Here’s a structured overview of its key features and technologies:

Core Features & Technologies

- Emission Compliance & Efficiency:

- IMO Tier 2 Compliance: Reduces NOx, SOx, and particulate emissions through optimized combustion and cooling.

- CMI High-Efficiency Supercharger & Intercooler: Enhances air intake compression and cooling, improving combustion efficiency and reducing fuel consumption.

- Low-Temperature Intercooler Technology: Lowers intake air temperature, increasing oxygen density for cleaner, more efficient combustion.

- Fuel System & Combustion:

- High Injection Pressure: Ensures fine fuel atomization for complete combustion, reducing emissions and improving efficiency.

- ESTC Electronic Oil Timing Control: Precisely adjusts injection timing, optimizing performance at low idle and reducing smoke.

- Low-Pressure Fuel Supply & Simplified Piping: Reduces system complexity and failure risk while maintaining reliability.

- Reliability & Durability:

- Overspeed Protection: Prevents mechanical damage from excessive RPM.

- Integrated Cylinder Block/Head Design: Minimizes failure points (e.g., head gasket issues) and enhances structural integrity.

- Advanced Lubrication System: Reduces friction and wear, extending engine life.

- Low Parasitic Power: Auxiliary systems consume minimal energy, maximizing usable power output.

- Modular & Maintenance-Friendly Design:

- Block Integration & Compact Structure: Simplifies installation in tight spaces and improves manufacturing consistency.

- Detachable, Reusable Components: Facilitates easy repairs and reduces lifecycle costs.

- High Reusability: Supports sustainability by minimizing waste during overhauls.

Performance Benefits

- Operational Efficiency: Fast starting, excellent acceleration, and strong transient response suit dynamic marine environments.

- Durability: Robust construction and low failure rate ensure longevity, critical for marine operations with limited maintenance access.

- Cost-Effectiveness: Reduced fuel consumption, emissions, and maintenance needs lower total ownership costs.

Applications

Ideal for commercial vessels, offshore platforms, and marine propulsion systems requiring compliance with modern emissions standards, high reliability, and long service intervals.

In summary, the QSK19 engine leverages cutting-edge engineering to balance performance, environmental compliance, and operational reliability, making it a competitive choice for demanding marine applications.