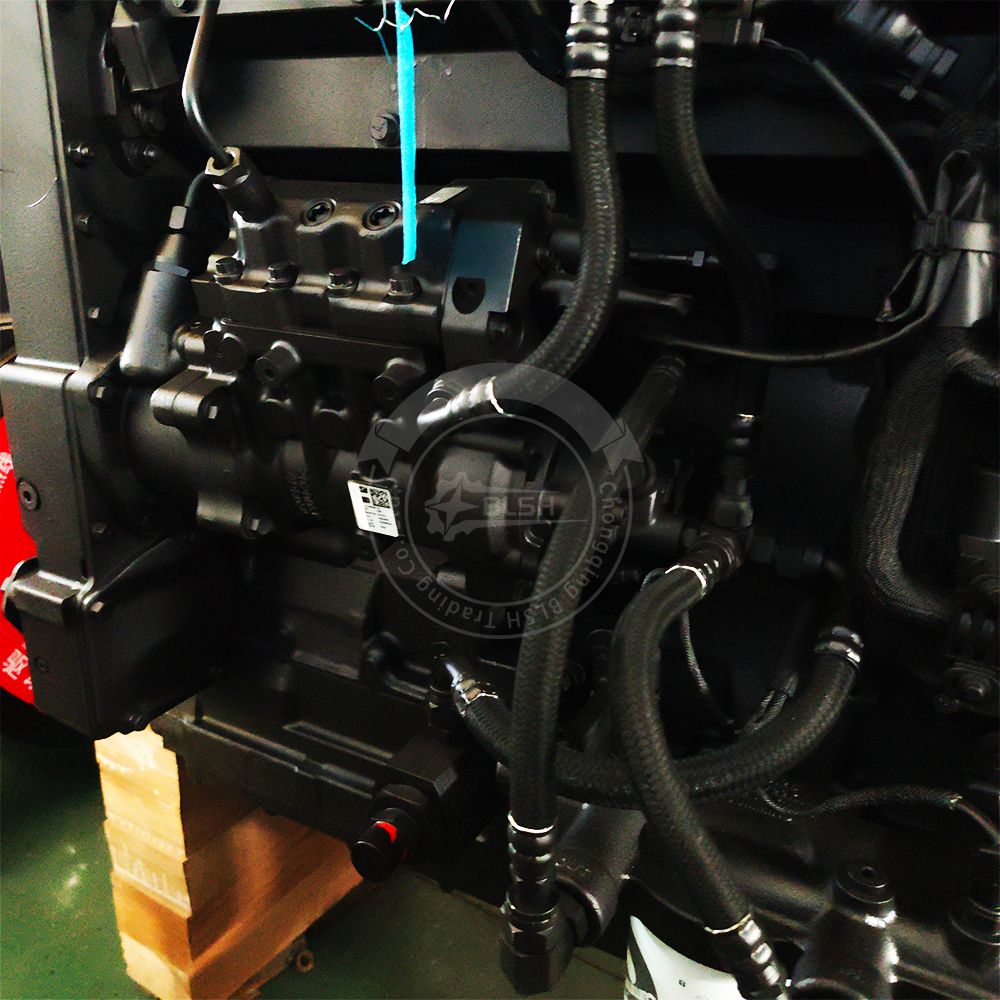

CCEC QSK19-G3-A Generator Engines

| Engine Model | QSK19-G3-A |

| Standby Power | 850 HP (634 kW) at 1500 RPM |

| Prime Power | 770 HP (574 kW) at 1500 RPM |

| Compression Ratio | 15.0 : 1 |

| Type | 4 Cycle; 6 Cylinder |

| Fuel System | CMS MCRS |

| Aspiration | Turbocharged & Aftercooled |

| Emission Standard | Euro II |

| Displacement | 19L |

| Bore * Stroke | 159 mm * 159 mm |

| Packing Size (L * W * H) | 1695 mm * 985 mm * 1723 mm |

General Infomation of CCEC QSK19-G3-A Generator Engines

| General Infomation of CCEC QSK19-G3-A Generator Engine | |||

| Engine Model | QSK19-G3-A | Configuration | D193103GX03 |

| Performance Curve | DS-4446 | CPL | 1485 |

| Type | 4-Cycle; In-line; 6-Cylinder Diesel | Aspiration | Turbocharged and Air to Air Aftercooled |

| Stroke * Bore | 159 mm * 159 mm / 6.25 in * 6.25 in | Displacement | 1159 in3 / 19.0 L |

| Compression Ratio | 15.0 : 1 | No. of Cylinders | 6 |

| Prime Power & Engine Speed | 770 HP (574 kW) at 1500 RPM | Continuous Power & Engine Speed | 450 HP (336 kW) at 1500 RPM |

| Standby Power & Engine Speed | 850 HP (634 kW) at 1500 RPM | Emissions | EPA Tier 2 NSPS |

| Installation Data of CCEC QSK19-G3-A Generator Engine | |||

| Wet Weight – Fan to Flywheel Engine | 4350 lb / 1973 kg | Dry Weight – Fan to Flywheel Engine | 4190 lb / 1900 kg |

| Date | 5Oct07 | Steady State Stability Band at Any Constant Load | +/- 0.25% |

| Moment of Inertia of Rotating Components – with FW 1109 Flywheel | 194.6 lbm.ft2 / 8.2 kg.m2 | Maximum Bending Moment at Rear Face of Block | 1000 lb.ft / 1356 N.m |

| Center of Gravity from Rear Face of Block | 23.55 in / 598.2 mm | Center of Gravity Above Crankshaft Centerline | 11.1 in / 281.9 mm |

| Maximum Static Loading at Rear Main Bearing | 2000 lb / 908 kg | Fan to Flywheel | 4953720 |

| Excludes Exhaust Noise; at Rated Load and 7 m (23 ft); 1500 RPM | 90.2 dBA | Exhaust Noise at 1 m Horizontally from Centerline of Exhaust Pipe Outlet Upwards at 45°; 1500 RPM | 118 dBA |

Engine Performance Data CCEC QSK19-G3-A Generator Engines

| Performance Data of CCEC QSK19-G3-A Generator Engine | |||||

| PRIME POWER | STANDBY | PRIME POWER | STANDBY | ||

| Governed Engine Speed | 1500 RPM | 1500 RPM | Exhaust Gas Flow | 4185 cfm / 1975 L/s | 4425 cfm / 2090 L/s |

| Engine Idle Speed | 700 – 900 RPM | 700 – 900 RPM | Air to Fuel Ratio (air : fuel) | 25.5 : 1 | 24.6 : 1 |

| Gross Engine Power Output | 770 HP / 574 kW | 850 HP / 634 kW | Radiated Heat to Ambient | 3285 BTU/min / 60 kW | 3515 BTU/min / 65 kW |

| Brake Mean Effective Pressure | 353 psi / 2434 kPa | 389 psi / 2682 kPa | Heat Rejection to Jacket Coolant | 12225 BTU/min / 215 kW | 12830 BTU/min / 230 kW |

| Piston Speed | 1562 ft/min / 7.9 m/s | 1562 ft/min / 7.9 m/s | Heat Rejection to Exhaust | 25365 BTU/min / 450 kW | 26095 BTU/min / 460 kW |

| Friction Horsepower | 57 HP / 43 kW | 57 HP / 43 kW | Heat Rejected to Fuel | 300 BTU/min / 5 kW | 300 BTU/min / 5 kW |

| Intake Air Flow | 1635 cfm / 775 L/s | 1720 cfm / 810 L/s | Heat Rejected to Aftercooler | 8490 BTU/min / 150 kW | 9355 BTU/min / 165 kW |

| Exhaust Gas Temperature | 945 °F / 505 °C | 960 °F / 515 °C | Charge Air Flow | 114 lb/min / 52 kg/min | 120 lb/min / 55 kg/min |

| Turbocharger Compressor Outlet Pressure | 82 in Hg / 278 kPa | 88 in Hg / 298 kPa | Maximum Expected Compressor Outlet Temperature | 426 °F / 219 °C | 446 °F / 230 °C |

| Engine Water Flow at Stated Friction Head External to Engine ( 3.0 psi Friction Head ) | 162 US gpm / 10.2 L/s | 162 US gpm / 10.2 L/s | Engine Water Flow at Stated Friction Head External to Engine ( Maximum Friction Head ) | 145 US gpm / 9.1 L/s | 145 US gpm / 9.1 L/s |

System Technical Data of CCEC QSK19-G3-A Generator Engines

| System Technical Data of CCEC QSK19-G3-A Generator Engine | ||

| Exhaust System | Maximum Back Pressure – 1500 RPM | 2.3 in Hg / 7.8 kPa |

| Air Induction System | Maximum Allowable Intake Air Restriction – With Clean Filter Element | 15 in H2O / 635 mm H2O |

| Maximum Allowable Intake Air Restriction – With Dirty Filter Element | 25 in H2O / 381 mm H2O | |

| Cooling System | Jacket Water Circuit Requirements | |

| Minimum Pressure Cap | 15 psi / 103 kPa | |

| Coolant Capacity — Engine Only | 11 US gal / 41.6 liter | |

| Standard Thermostat (Modulating) Range | 181 – 203 °F / 83 – 95°C | |

| Maximum Coolant Friction Head External to Engine | 5 psi / 35 kPa | |

| Maximum Top Tank Temperature for Standby / Prime Power | 212 – 220 °F / 100 – 104 °C | |

| Maximum Static Head of Coolant Above Engine Crank Centerline | 60 ft. / 18.3 m | |

| Charge Air Cooler Requirements | ||

| Maximum Intake Manifold Temperature @ 77 °F (25 °C) Ambient – 1500 RPM | 115 °F / 46 °C | |

| Maximum Temp. Rise Between Engine Air Intake and Intake Manifold – 1500 RPM | 38 °F / 21 °C | |

| Maximum Air Pressure Drop from Turbo Air outlet to Intake Manifold – 1500 RPM | 3 in Hg / 10.2 kPa | |

| Maximum Intake Manifold Temperature for Engine Protection (Warning Threshold) | 180 °F / 82 °C | |

| Lubrication System | Oil Pressure @ Idle Speed | 20 PSI / 138 kPa |

| Oil Pressure @ Governed Speed | 40 – 60 PSI / 276 – 414 kPa | |

| Maximum Oil Consumption | 250 °F / 121 °C | |

| Oil Capacity with OP 4084 Oil Pan : High – Low | 19 – 17 US gal / 72 – 64 litre | |

| Total System Capacity (Including Combo Filter) | 22.3 US gal / 84.4 litre | |

| Fuel System | Type Injection System | CMS MCRS |

| Maximum Return Fuel Flow | 66 US gph / 250 litre/hr | |

| Maximum Fuel Inlet Temperature | 180 °F / 82 °C | |

| Maximum Fuel Flow to Injector Pump | 102 US gph / 386 litre/hr | |

| Maximum Restriction at Lift Pump (clean/dirty filter) | 5/9 in Hg / 127/228 mm Hg | |

| Maximum Allowable Head on Injector Return Line (Consisting of Friction Head and Static Head) | 10 in Hg / 254 mm Hg | |

| Electrical System | Battery Charging System, Negative Ground | 35 ampere |

| Cranking Motor (Heavy Duty, Positive Engagement) | 24 volt | |

| Maximum Allowable Resistance of Cranking Circuit | 0.002 ohm | |

| Minimum Recommended Battery Capacity-Cold Soak @ 50 °F (10 °C) and Above | 600 0 °F CCA | |

| Minimum Recommended Battery Capacity-Cold Soak @ 32 °F to 50 °F (0 °C to 10 °C) | 640 0 °F CCA | |

| Minimum Recommended Battery Capacity-Cold Soak @ 0 °F to 32 °F (-18 °C to 0 °C) | 900 0 °F CCA | |

| COLD START CAPABILITY | Minimum Ambient Temperature for Aided (with Coolant Heater) Cold Start within 10 seconds | N/A |

| Minimum Ambient Temperature for Unaided Cold Start | 10 °F / -12 °C | |

CCEC QSK19-G3-A Generator Engines Product Advantages

Outstanding Performance

Equipped with the world-leading high-pressure common rail fuel system and fully electronic control modules, the engine achieves exceptional power and transient response through ultra-high fuel injection pressure, optimized vortex and harmonic intake ports, and Cummins’ proprietary high-pressure-ratio efficient turbocharger. It demonstrates enhanced adaptability to altitude, temperature, and load variations.

Features high torque, robust power, rapid transient response, and superior fuel efficiency.

Excellent Durability

The cylinder block and cylinder head are designed with high-strength integration to minimize failure rates, ensuring long-lasting reliability and an outstanding reputation.

The pre-lubrication system, Centriguard centrifugal filter, CENTINEL continuous oil renewal system, and dual-stage Fleetguard combination oil filter extend maintenance intervals while reducing startup failure rates.

High Reliability

Modular integration, compact structure, low failure rates, reduced vibration, and low noise. The engine maintains optimal performance across varying altitudes and load conditions.

Emission Compliance

An optimized combustion chamber design enables the engine to achieve exceptional emission levels without requiring aftertreatment systems. It has been certified under China’s National Stage III Emission Standard for non-road applications.

Convenient Maintenance

The INSITE engine monitoring and diagnostics software, based on the Windows operating system, offers a user-friendly interface and flexibility for rapid fault diagnosis.

A modular design with compact, block-based integration ensures easy disassembly and component reuse. Shared components across the platform enhance parts commonality.

Six-cylinder single-head integrated design with modularized structure ensures compactness. Components are detachable and highly reusable.