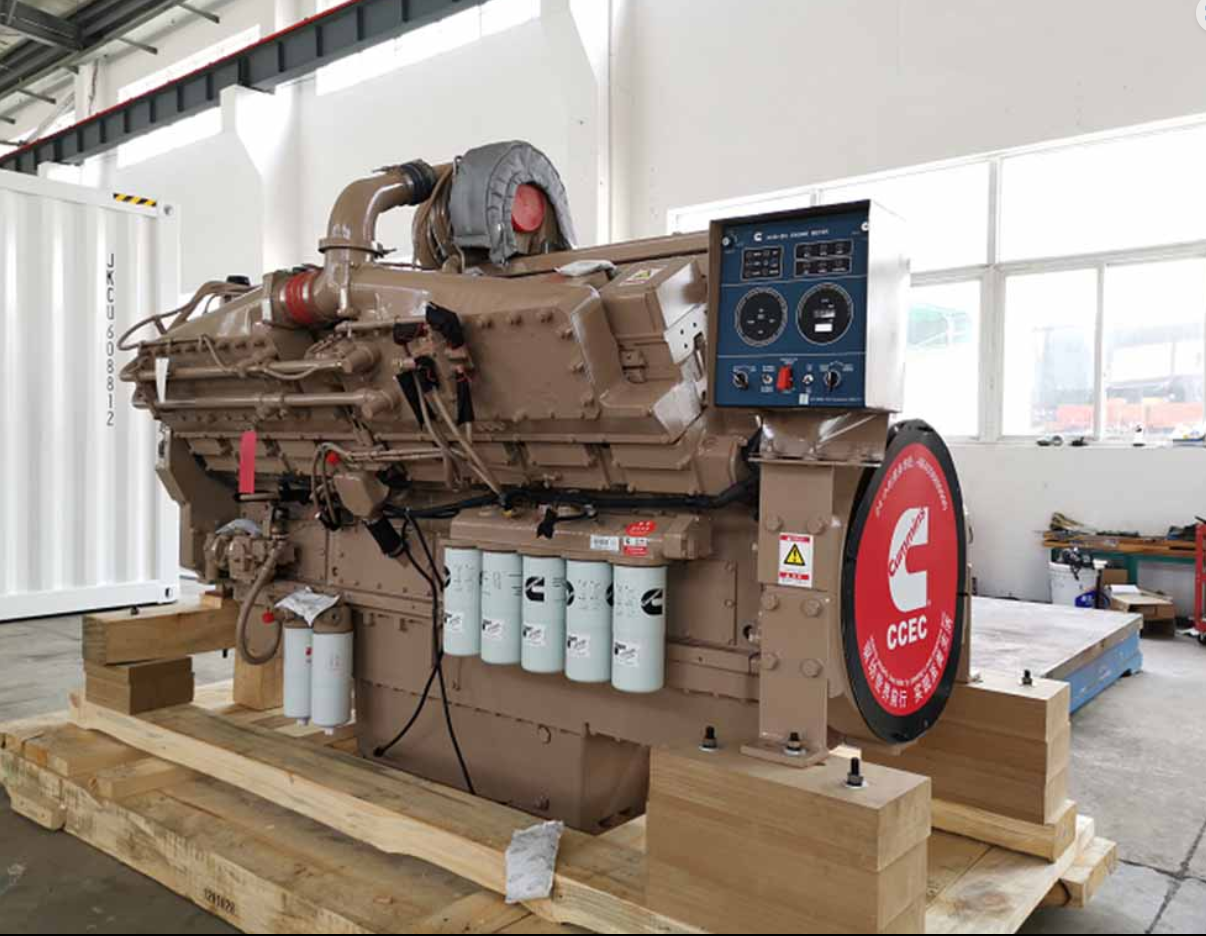

CCEC KTA50-M2-1875 Marine Engine

| Engine Model | KTA50-M2-1875 |

| Advertised Power | 1398 kW (1875 HP) @ 1950 RPM |

| Compression Ratio | 14.5 : 1 |

| Type | 4 Cycle; 16 Cylinder |

| Fuel System | PT |

| Aspiration | Turbocharged / LTA |

| Emission Standard | Euro II |

| Displacement | 50L |

| Bore * Stroke | 159 mm * 159 mm |

| Packing Size (L * W * H) | 2794 mm * 1507 mm * 1846 mm |

General Infomation of CCEC KTA50-M2-1875 Marine Engine

| General Infomation of CCEC KTA50-M2-1875 Marine Main Engine | |||

| Engine Model | KTA50-M2-1875 | Configuration | D283033MX02 |

| Curve No. | M – 6277 | CPL Code | 8063 |

| Displacement | 3068 in3 / 50 L | Bore * Stroke | 159 mm * 159 mm / 6.25 in * 6.25 in |

| Fuel System | PT (Centry And V.S.) | Cylinders | 16 |

| Advertised Power | 1398 kW (1875 HP) @ 1950 RPM | Aspiration | Turbocharged / Low Temperature Aftercooled |

| Rating Type | Medium Continuous Duty | Rated Engine Torque | 5050 lb.ft / 6847 N.m |

| Peak Engine Torque @ 1500 RPM | 5402 lb.ft / 7324 N.m | Brake Mean Effective Pressure | 248 PSI / 1711 kPa |

| Indicated Mean Effective Pressure | 498 PSI / 3435 kPa | Maximum Allowable Engine Speed | 2375 RPM |

| Maximum Torque Capacity from Front of Crank2 | 3202 lb.ft / 4341 N.m | Compression Ratio | 13.9 : 1 |

| Piston Speed | 2031 ft/min / 10.3 m/sec | Firing Order | 1R-1L-3R-3L-2R-2L-5R-4L-8R-8L-6R-6L-7R-7L-4R-5L |

| Normal Idle Speed Variation | N / A | High Idle Speed Range Minimum | N / A |

| Weight (Dry) – Engine Only – Average | 11389 lb. / 5166 kg | Weight (Dry) – Engine With Heat Exchanger System – Average | 12659 lb. / 5742 kg |

| Weight Tolerance (Dry) Engine Only | 10.0 3xStd Dev(± %) | Default Droop Value | 6 % |

| Minimum Droop Allowed | N / A | Maximum Droop Allowed | N / A |

| High Speed Governor Break Point | 2010 RPM | Minimum Idle Speed Setting | 650 RPM |

| Normal Idle Speed Variation | ± 25 RPM | High Idle Speed Range – Minimum | 2010 RPM |

| High Idle Speed Range – Maximum | 2184 RPM | Rated Power Production Tolerance | ± 3 % |

| Average Noise Level – Top (Idle) | 100 dBA @ 1m | Average Noise Level – Top (Rated) | 110 dBA @ 1m |

| Average Noise Level – Right Side (Idle) | 98 dBA @ 1m | Average Noise Level – Right Side (Rated) | 109 dBA @ 1m |

| Average Noise Level – Left Side (Idle) | 99 dBA @ 1m | Average Noise Level – Left Side (Rated) | 108 dBA @ 1m |

| Average Noise Level – Front (Idle) | 98 dBA @ 1m | Average Noise Level – Front (Rated) | 108 dBA @ 1m |

Scopes of Supply CCEC KTA50-M2-1875 Marine Engine

| Scopes of Supply of CCEC KTA50-M2-M1875 Marine Main Engine | |||

| Exhaust System | 1. Silencer | Lubricating System | 1. Oil Pump |

| 2. Bellows | 2. Oil Filter | ||

| Fuel System | 1. Fuel Pump | Starting System | 1. Starter Motor |

| 2. Oil Cut Solenoid Valve | 2. Fywheel Housing | ||

| 3. Fuel Filter | 3. Flywheel | ||

| Charging System | 1. Alternator | Control System | 1.Stadnby Control Panel |

| Cooling System | 1. Seawater Pump | ||

| 2. Heat Exchanger | |||

System Technical Data of CCEC KTA50-M2-1875 Marine Engine

| System Technical Data of CCEC KTA50-M2-1875 Marine Main Engine | ||

| Fuel System | Avg. Fuel Consumption – ISO 8178 E3 Standard Test Cycle | 55.7 GAL/hr / 248.6 L/hr |

| Fuel Consumption at Rated Speed | 93.8 GAL/hr / 354.9 L/hr | |

| Approximate Fuel Flow to Pump | 167 GAL/hr / 632.2 L/hr | |

| Maximum Allowable Fuel Supply to Pump Temperature | 140 °F / 60 °C | |

| Approximate Fuel Flow Return to Tank | 73.2 GAL/hr / 277.2 L/hr | |

| Approximate Fuel Flow Return to Tank Temperature | 158 °F / 70.3 °C | |

| Maximum Heat Rejection to Drain Fuel | 4.3 kW / 245 Btu/min | |

| Fuel Transfer Pump Pressure Range | N / A | |

| Fuel Pressure – Pump Out / Rail Mechanical Gauge | 161 PSI / 1113 kPa | |

| Fuel Pressure – Pump Out / Rail Insite Reading | 165 PSI / 1141 kPa | |

| Air System | Intake Manifold Pressure | 66 in. Hg / 225 kPa |

| Intake Air Flow | 4213 CFM / 1988 L/sec | |

| Heat Rejection to Ambient | 4681 BTU/min / 82 kW | |

| Exhaust System | Exhaust Gas Flow | 10119 CFM / 4773 L/sec |

| Exhaust Gas Temperature (Turbine Out) | 847 °F / 453 °C | |

| Heat Rejection to Exhaust (Manifold) | 1186 °F / 642 °C | |

| Emissions (in accordance with ISO 8178 Cycle E3) | ||

| NOx (Oxides of Nitrogen) | 9.61 g/kW·hr / 7.17 g/HP·hr | |

| HC (Hydrocarbons) | 0.26 g/kW·hr / 0.19 g/HP·hr | |

| CO (Carbon Monoxide) | 0.60 g/kW·hr / 0.45 g/HP·hr | |

| PM (Particulate Matter) | N / A | |

| Cooling System | Sea Water Pump Specifications | MAB 0.08.17 – 07 / 16 / 2001 |

| Pressure Cap Rating (With Heat Exchanger Option) | 15 PSI / 103 kPa | |

| Max. Coolant Outlet Pressure from the Engine | 37 PSI / 256 kPa | |

| Max. Pressure Drop Across Any External Cooling System Circuit | 5 PSI / 34 kPa | |

| Engines with Low Temperature Aftercooling (LTA ) – Main Engine Circuit | ||

| Coolant Flow to Main Cooler (with blocked open thermostat) | 320 GAL/min / 1211 L/min | |

| Standard Thermostat Operating Range (Start to Open) | 180 °F / 82 °C | |

| Standard Thermostat Operating Range (Full Open) | 202 °F / 95 °C | |

| Heat Rejection to Engine Coolant3 | 30631 BTU/min / 538 kW | |

| Engines with Low Temperature Aftercooling (LTA ) – Aftercooler (LTA) Circuit | ||

| Coolant Flow to LTA Cooler (with blocked open thermostat) | 82 GAL/min / 310 L/min | |

| Standard Thermostat Operating Range (Start to Open) | 150 °F / 66 °C | |

| Standard Thermostat Operating Range (Full Open) | 175 °F / 80 °C | |

| Heat Rejection to Engine Coolant3 | 15729 BTU/min / 276 kW | |

| Maximum Coolant Inlet Temperature from LTA Cooler | 160 °F / 71 °C | |

CCEC KTA50-M2-1875 Marine Engine Product Advantages

Excellent Durability

The cylinder block and head adopt high-strength integrated design, reducing failure rates. Durable and has earned an excellent reputation.

Outstanding Performance

Equipped with an advanced PT fuel system and ultra-high injection pressure, it features unique advantages such as overspeed protection, low-pressure fuel supply, fewer pipelines, and low failure rates. This ensures optimal fuel atomization and efficient combustion, delivering high energy-saving performance. The STC oil timing control valve precisely adjusts timing, improving combustion and reducing smoke emissions during low-idle conditions.

Exhaust System

Chongqing Cummins marine engines are designed with a rational exhaust system. The wet turbocharger and water-cooled exhaust pipes effectively reduce surface temperatures, complying with SOLAS safety regulations.

Easy Maintenance

Modular design with compact and integrated components. Parts are detachable with high reusability. Shared platform design ensures high parts commonality.

Emission Compliance

Compliant with IMO Tier II emission standards. Features a marine-optimized turbocharger and intercooler from Chongqing Cummins, paired with low-temperature intercooling technology. This enhances operational efficiency, reduces fuel consumption and emissions, and improves engine reliability.

Classification Society Certifications

Certified by multiple international classification societies, including CCS and BV.