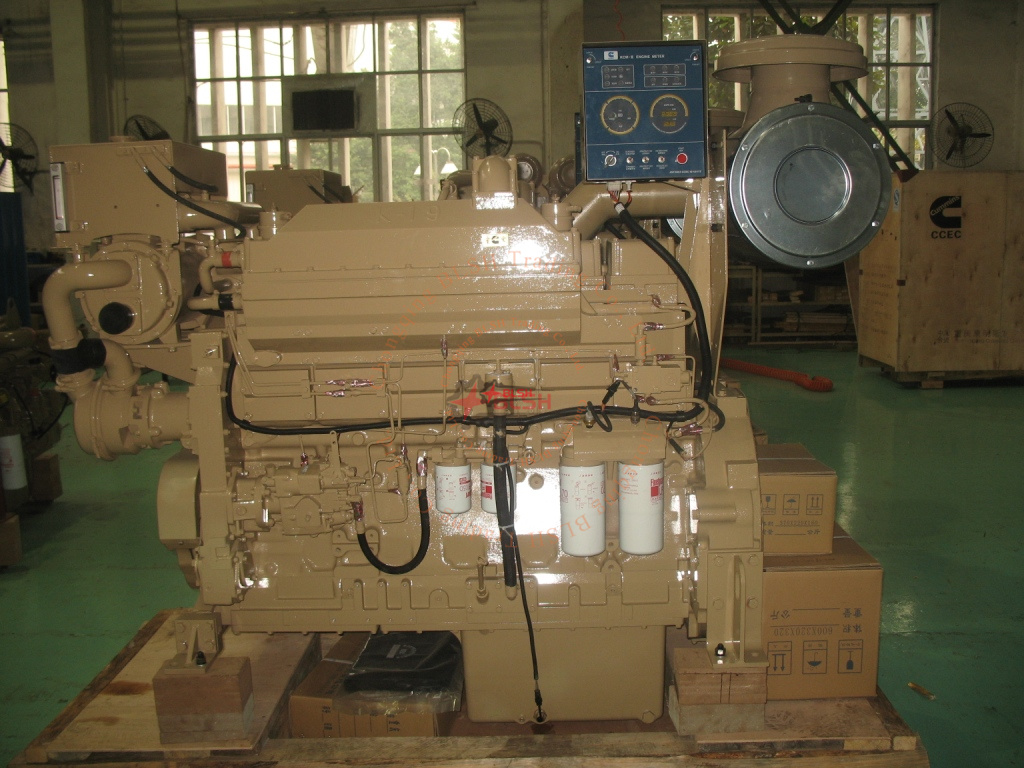

CCEC KTA19 – M550 Marine Engine

| Engine Model | KTA19 – M550 |

| Advertised Power | 410 kW (550 HP) @ 2100 RPM |

| Compression Ratio | 14.5 : 1 |

| Type | 4 Cycle; 6 Cylinder |

| Fuel System | PT |

| Aspiration | Turbocharged & Aftercooled |

| Emission Standard | Euro II |

| Displacement | 14L |

| Bore * Stroke | 159 mm * 159 mm |

| Packing Size (L * W * H) | 1534 mm * 781 mm * 1355 mm |

General Infomation of CCEC KTA19 – M550 Marine Engine

| General Infomation of CCEC KTA19 – M550 Marine Main Engine | |||

| Engine Model | KTA19 – M550 | Configuration | D193080MX02 |

| Curve No. | M – 488 | CPL Code | CQ415 |

| Displacement | 1150 in3 / 19 L | Bore * Stroke | 159 mm * 159 mm / 6.25 in * 6.25 in |

| Fuel System | PT | Cylinders | 6, in Line |

| Advertised Power | 410 kW (550 HP) @ 2100 RPM | Aspiration | Turbocharged & Water – Air Intercooler |

| Rating Type | Medium Continuous | Peak Engine Torque @ 1500 RPM | 1513 lb.ft / 2052 N.m |

| Brake Mean Effective Pressure | 179 PSI / 1233 kPa | Minimum Idle Speed Setting | 625 – 675 RPM |

| Normal Idle Speed Variation | ± 25 RPM | High Idle Speed Range Minimum | 2234 RPM |

| High Idle Speed Range Maximum | 2554 RPM | Compression Ratio | 14.5 : 1 |

| Piston Speed | 2185 ft/min / 11.1 m/sec | Weight (Dry) – Engine Only – Average | 4566 lb. / 2073 kg |

| Weight (Dry) – Engine With Heat Exchanger System – Average | 4958 lb. / 2251 kg | Installation Diagram No | N / A |

Scopes of Supply CCEC KTA19 – M550 Marine Engine

| Scopes of Supply of CCEC KTA19 – M550 Marine Main Engine | |||

| Exhaust System | 1. Silencer | Lubricating System | 1. Oil Pump |

| 2. Bellows | 2. Oil Filter | ||

| Fuel System | 1. Fuel Pump | Starting System | 1. Starter Motor |

| 2. Oil Cut Solenoid Valve | 2. Fywheel Housing | ||

| 3. Fuel Filter | 3. Flywheel | ||

| Charging System | 1. Alternator | Control System | 1.Stadnby Control Panel |

| Cooling System | 1. Seawater Pump | ||

| 2. Heat Exchanger | |||

System Technical Data of CCEC KTA19 – M550 Marine Engine

| System Technical Data of CCEC KTA19 – M550 Marine Main Engine | ||

| Fuel System | Avg. Fuel Consumption – ISO 8178 E3 Standard Test Cycle | 20.2 GAL/hr / 76.4 L/hr |

| Fuel Consumption at Rated Speed | 29.1 GAL/hr / 110 L/hr | |

| Approximate Fuel Flow to Pump | 87 GAL/hr / 330 L/hr | |

| Maximum Allowable Fuel Supply to Pump Temperature | 140 °F / 60 °C | |

| Approximate Fuel Flow Return to Tank Temperature | 126 °F / 52 °C | |

| Maximum Heat Rejection to Drain Fuel | N / A | |

| Fuel Pressure – Pump Out / Rail Mechanical Gauge | 149 PSI / 1027 kPa | |

| Air System | Intake Manifold Pressure | 59 in. Hg / 200 kPa |

| Intake Air Flow | 1563 CFM / 738 L/sec | |

| Heat Rejection to Ambient | 1195 BTU/min / 21 kW | |

| Exhaust System | Exhaust Gas Flow | 3887 CFM / 1835 L/sec |

| Exhaust Gas Temperature (Turbine Out) | 743 °F / 395 °C | |

| Heat Rejection to Exhaust (Manifold) | 1006 °F / 541 °C | |

| Emsission (in accordance with ISO 8178 Cycle E3) | ||

| NOx (Oxides of Nitrogen) | 4.28 g/HP.hr / 5.73 g/kW.hr | |

| Cooling System | Sea Water Pump Specifications | MAB 0.08.17 – 07 / 16 / 2001 |

| Pressure Cap Rating (With Heat Exchanger Option) | 7 PSI / 50 kPa | |

| Engines with Low Temperature Aftercooling (if applicable) – Main Cooler | ||

| Coolant Flow to Engine Heat Exchanger / Keel Cooler | 175 GAL / 664 L/min | |

| Standard Thermostat Operating Range (Start to Open) | 180 °F / 82 °C | |

| Standard Thermostat Operating Range (Full Open) | 203 °F / 95 °C | |

| Heat Rejection to Engine Coolant3 | 11953 BTU/min / 210 kW | |

| Engines with Low Temperature Aftercooling (if applicable) – LTA Cooler | ||

| Coolant Flow to Engine Heat Exchanger / Keel Cooler | 30 GAL / 114 L/min | |

| Standard Thermostat Operating Range (Start to Open) | 156 °F / 69 °C | |

| Standard Thermostat Operating Range (Full Open) | 172 °F / 78 °C | |

| Heat Rejection to Engine Coolant3 | 6603 BTU/min / 116 kW | |

| Maximum Coolant Inlet Temperature from LTA Cooler | 145 °F / 63 °C | |

CCEC KTA19 – M550 Marine Engine Product Advantages

Excellent Durability

The cylinder block and head adopt high-strength integrated design, reducing failure rates. Durable and has earned an excellent reputation.

Outstanding Performance

Equipped with an advanced PT fuel system and ultra-high injection pressure, it features unique advantages such as overspeed protection, low-pressure fuel supply, fewer pipelines, and low failure rates. This ensures optimal fuel atomization and efficient combustion, delivering high energy-saving performance. The STC oil timing control valve precisely adjusts timing, improving combustion and reducing smoke emissions during low-idle conditions.

Exhaust System

Chongqing Cummins marine engines are designed with a rational exhaust system. The wet turbocharger and water-cooled exhaust pipes effectively reduce surface temperatures, complying with SOLAS safety regulations.

Easy Maintenance

Modular design with compact and integrated components. Parts are detachable with high reusability. Shared platform design ensures high parts commonality.

Emission Compliance

Compliant with IMO Tier II emission standards. Features a marine-optimized turbocharger and intercooler from Chongqing Cummins, paired with low-temperature intercooling technology. This enhances operational efficiency, reduces fuel consumption and emissions, and improves engine reliability.

Classification Society Certifications

Certified by multiple international classification societies, including CCS and BV.